Epistemy Press books use a fictitious company called Global Bike Inc. (GBI) to illustrate complex concepts in a simple, pragmatic way. The following is an overview of GBI’s structure, business processes, products, customers, and vendors. Although GBI is a fictitious company, it very closely resembles the challenges that a real-world company faces on a daily basis.

Company History

John Davis is a world-renowned bicyclist and a mountain racing champion. He created a company in the United States to produce trail bikes. Peter Weiss of Germany is an engineer who not only races road bikes but also designs bike frames. He formed a company to manufacture lightweight touring bike frames. John and Peter met in 2000 and merged their two companies to form GBI.

The Business

GBI serves the professional and “prosumer” cyclist market for mountain (off-road) and touring (road) bikes. GBI is known for its carbon composite frames, which are strong, lightweight, and low maintenance. These frames are features in the professional line of bikes. In contrast, the deluxe line of bikes uses an aluminum frame. Figure 2 shows the Professional Touring Bike in Black. This bike features a carbon composite bike frame. It typically sells for 3,200 USD in the United States.

Figure 2: PRTR1000 Professional Touring Bike Black

Figure 2: PRTR1000 Professional Touring Bike Black

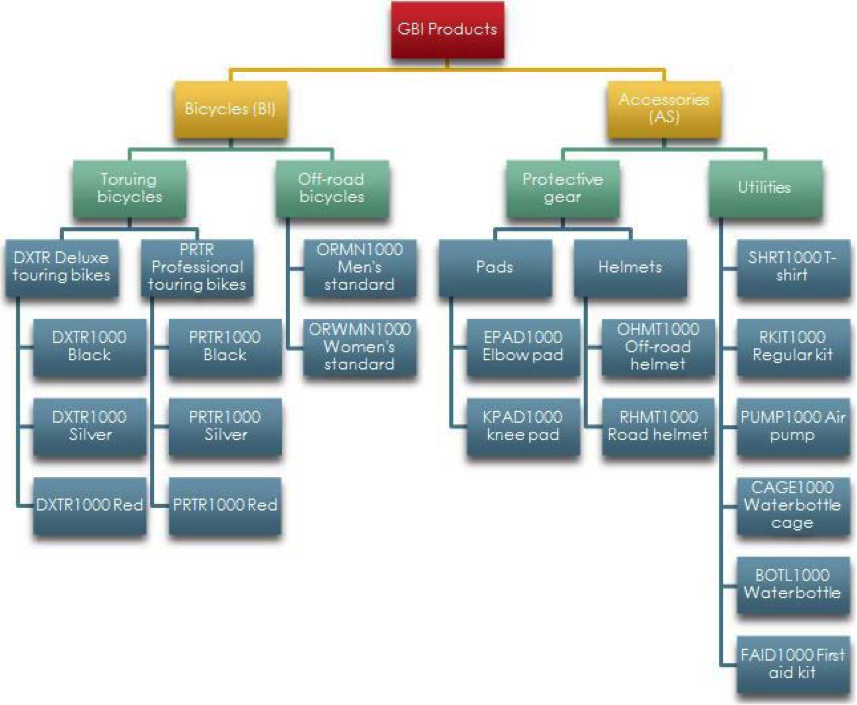

GBI also sells bicycling accessories to their customers. Helmets, first aid kits, shirts, and water bottles are examples of these non-bike products. Figure 3 displays the complete list of GBI products.

Innovation, safety, reliability, and performance are the core of GBI’s business. Adhering to this core has kept the company competitive in an environment of increasing threats from other companies and knock-offs. GBI does not sell products directly to consumers. Instead, it relies on its high-end customers (partners).

Figure 3: GBI Product List

Figure 3: GBI Product List

Organizational Structure

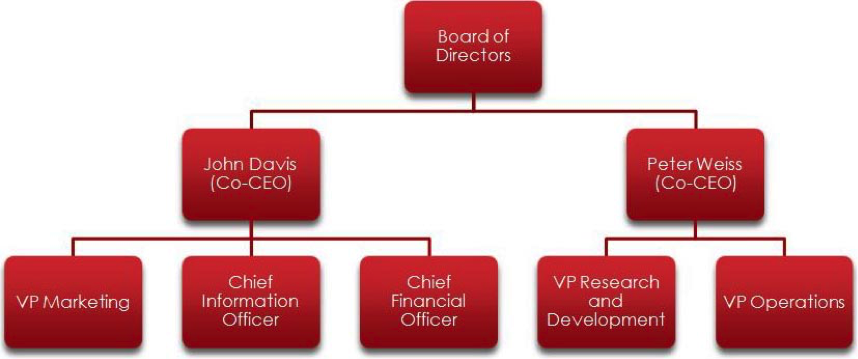

John and Peter are the co-CEOs of GBI. The company has approximately 100 employees. Roughly two-thirds of them work in the United States; the rest are employed in Germany. Figure 4 indicates the top-level organizational structure of GBI.

Figure 4: Top-Level Organizational Structure

Figure 4: Top-Level Organizational Structure

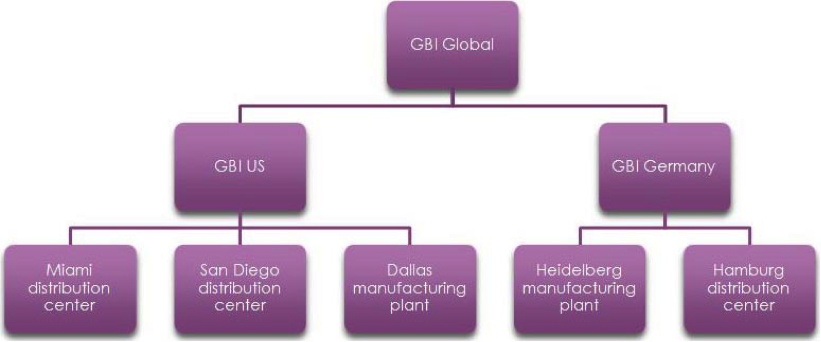

GBI’s headquarters are located in Dallas (Figure 5 displays the business structure), and GBI is registered as a U.S. company following U.S. generally accepted accounting standards (GAAP). GBI operates a subsidiary company, GBI Europe, which is based in Heidelberg and is subject to international accounting standards (IFRS) and German tax regulations.

Materials planning, finance, administration, HR, and IT functions are consolidated at the Dallas headquarters. The Dallas facility manufactures products for the U.S. and export markets, and its warehouse manages product distribution for the central U.S. and internet retailers. GBI also maintains warehouses for shipping and export in both San Diego and Miami. San Diego handles West Coast distribution and exports for Asia, and Miami handles East Coast distribution and Latin America exports.

GBI Europe is headquartered in Heidelberg, Germany (DE). The majority of research and development for all of GBI is housed in the Heidelberg offices. Heidelberg is also the primary GBI manufacturing facility in Europe. The Heidelberg warehouse handles all shipping for southern Europe. The Hamburg warehouse handles all shipping for the United Kingdom, Ireland, the Middle East, and Africa.

Figure 5: GBI Business Structure

Business Partners (Customers and Vendors)

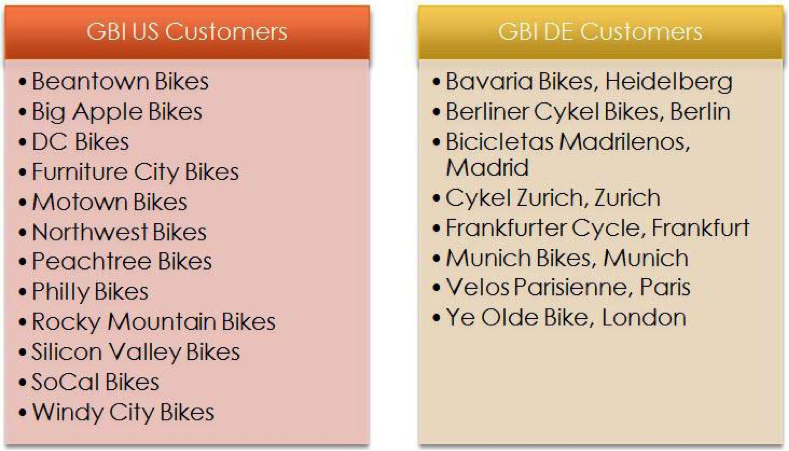

Given the highly specialized nature of GBI’s bicycles and the personalized needs of riders, GBI sells its bikes exclusively through well-known and respected independent bicycle dealers (IBDs). These dealers employ staff members who are experts in off-road and tour racing to help consumers choose the right GBI bike and accessories for their individual needs. Figure 6 displays a list of these customers.

Figure 6: GBI Customer List

Due to the technical nature of its products, GBI has embraced the internet primarily as an information channel, maximizing its potential for educating consumers and partners and marketing its products to a global audience. The company has limited its internet sales due to the complex tax issues associated with selling products in multiple states and countries.

Because reliability is a hallmark of GBI products, the company depends on highly selective vendors, or suppliers, of raw materials and trading goods. Figure 7 displays a list of GBI vendors.

Figure 7: GBI Vendor List

Production Plants

GBI operates two production facilities, Dallas and Heidelberg. Each facility has three assembly lines and each line can produce approximately 1,000 bikes per year. Total production capacity is roughly 6,000 bikes per year, but it can be increased by 15%-20% by authorizing overtime hours and hiring part-time workers. GBI has outsourced the production of both off-road and touring frames and the carbon composite wheels to trusted partners who have specialized facilities to fabricate the complex materials used. GBI maintains highly collaborative research and design relationships with these specialty partners to ensure that innovations in both material and structural capabilities are incorporated into the frames. GBI primarily assembles semi-finished goods into finished goods at its production facilities. Finished goods are either stored in the local warehouse or shipped to other regional distribution centers to fulfill customer orders.